Types of Yukata-Fabrics-

Tokuoka, Coma, Shijira (Crepe), Tsumugi, Cotton Bashō, Hemp, Silk Kōbai, Cotton Kōbai, Ōshū Kasuri, Cotton Ro

Chikusen Yukata Items

White-ground Coma, Dyed-ground Coma, Coma Rōketsu, Coma Tamamushi (Iridescent), Tsumugi Yukata, Cotton Bashō Tamamushi

Kōbai Komon, Ōshū Komon, Shijira Komon Chūgata, Ro Komon Chūgata, Silk Kōbai Komon, Hemp Komon, Ro Nagaita, Shijira Nagaita, etc.

Around 50 types of items and approximately 1,000 patterns.

The Phantom Dyeing Technique

By passing fabric between two rotating rollers etched with different patterns, the dyeing process produces distinct designs on both the front and back sides. This reversible dyeing technique has been passed down since the Taishō era.

Yarn-dyed Yukata

ーNagaita Chūgata

"Nagaita Chūgata" refers to a traditional yukata dyeing method from the Edo period.

Nowadays, we often encounter items labeled “Nagaita Chūgata,” but unfortunately, many differ from the genuine technique. Authentic Nagaita Chūgata uses a single 6.5-meter board of Japanese fir, on which the fabric is laid. A mid-sized stencil (approx. 40 cm square), larger than those used for komon, is applied separately to both front and back sides with resist paste. After aligning the front and back patterns perfectly, the fabric is immersed in an indigo vat for dyeing.

This precise alignment is known as "ura ga kaeru" ("the reverse comes through"), which is the essence of true Nagaita Chūgata.

Please be careful not to be misled—only a limited number of Chikusen yukata truly qualify as Nagaita Chūgata.

Originating in the Edo period and gaining great popularity in the Meiji era, this became the mainstream style of Edo yukata.

Designs include bold, hand-drawn motifs as well as small, classic patterns passed down from old komon stencils. It is a chic, double-sided stencil-dyed yukata made using natural indigo.

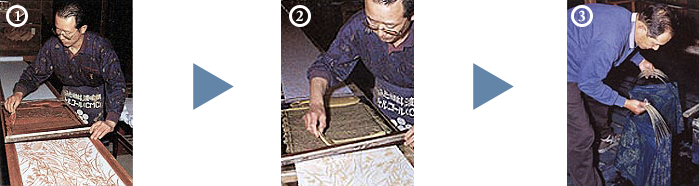

Dyeing Process of Nagaita Chūgata

1. Stencil is applied on fabric stretched over a longboard (approx. 7m).

2. Resist paste is applied to the entire 12m fabric; then the fabric is turned over.

3. A second resist application is made, aligning the back to the front pattern precisely—otherwise, the design will blur after dyeing.

4. The fabric, pasted on both sides, is dipped 3–5 times into an indigo vat. (Any more, and the paste will dissolve.)

Photos from “Utsukushii Kimono” Summer 2001 issue

Indigo develops its color through oxidation. Hence, freshly dyed yukata may not be fully colored to the core.

Ideally, we recommend wearing pieces that have been aired for 1–2 years.

Chusen (Pour Dyeing)

Originating in the late Meiji 20s (1890s), chusen is a unique dyeing technique used for tenugui and yukata, involving pouring dye.

The picturesque beauty of the indigo chusen yukata—this is the epitome of what defines yukata.

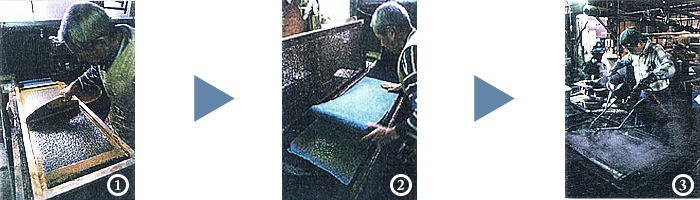

1. Resist paste is applied through a stencil held in a wooden frame.

2. The fabric is folded like an accordion (byōbu-datami), and resist is applied repeatedly.

3. After resist application, the fabric is placed on a dyeing table.

4. Dye is poured via a watering can and forced through the fabric using compressed air.

Photos from Shogakukan’s 1999 “Sarai” Issue 11

Though only a few bolts can be dyed by hand per day, this technique was revolutionary for yukata production and remains a durable dyeing method suitable for washing summer garments.

Hikizome (Brush Dyeing)

Originally used for solid-color and stencil dyeing, this method is employed at Chikusen particularly for Kōbai Komon and Ōshū Komon. Compared to shigoki-zome, this method yields a more beautiful finish and is thus used despite being more labor-intensive.

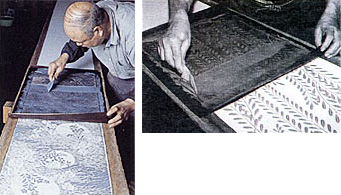

1. Stencil is applied to fabric stretched on a longboard (approx. 7m), and paste is applied successively. Photos: Left - “Utsukushii Kimono” 2001 Summer issue; Right - “Otoko no Kakurega” 1997, Zoukeisha

2. Brush dyeing is done over the pasted areas.

Photo: “Utsukushii Kimono” 2001 Summer issue

These garments are more like stylish summer outerwear than yukata.

Chemical dyes (rather than natural dyes) are used, allowing them to be hand-washed in cold water.

Unlike yukata, the dye does not penetrate to the reverse side.

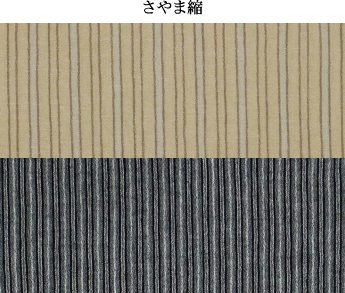

Yarn-dyed Textiles

Yarn-dyeing (sakizome) refers to dyeing the yarn before weaving it into fabric. In contrast, techniques like chusen and hikizome apply dye after the fabric is woven. Yarn-dyed fabrics are characterized by plaid, stripes, or geometric kasuri patterns.

Rōketsu-zome (Wax-resist Dyeing)

This technique resembles chusen in that paste is applied to resist dyeing. Here, melted wax is used instead, and the charm lies in the natural cracks that appear in the wax, creating unique patterns.

Shigoki-zome (Spatula Dyeing)

A dyeing technique in which a soft paste mixed with dye is spread over the entire fabric using a spatula called shigoki-bera.Only the surface is dyed—reverse side remains white.This is often used for dyeing the base color of silk kōbai komon and picture yukata.

1. Fabric is placed on a shigoki platform; paste is applied with a spatula.

2. To prevent paste layers from sticking, sawdust is sprinkled over the surface.

3. Fabric is then steamed in a box for about 5 minutes (depending on humidity, color, and pattern) to fix the dye.

Copyright©2026 CHIKUSEN CO.,Ltd. All Rights Reserved.